As the temperatures drop and winter approaches, it’s essential for lawn care professionals to prepare their spray equipment for the cold months ahead. Proper maintenance during the winter can help ensure that your spray rigs are ready for work when spring rolls around. Neglecting maintenance now can lead to costly repairs and downtime later. In this article, we’ll guide you through the steps of cold-weather equipment maintenance to protect your investment and get ready for the next season.

1. Clean Thoroughly

Before storing your spray rig for the winter, give it a thorough cleaning. Remove residue, dirt, and chemicals from all surfaces, including the tank, hoses, and ancillary equipment. A clean rig is less likely to suffer corrosion and damage during storage. Pay special attention to nozzles, screens, and filters, as these can become clogged over time.

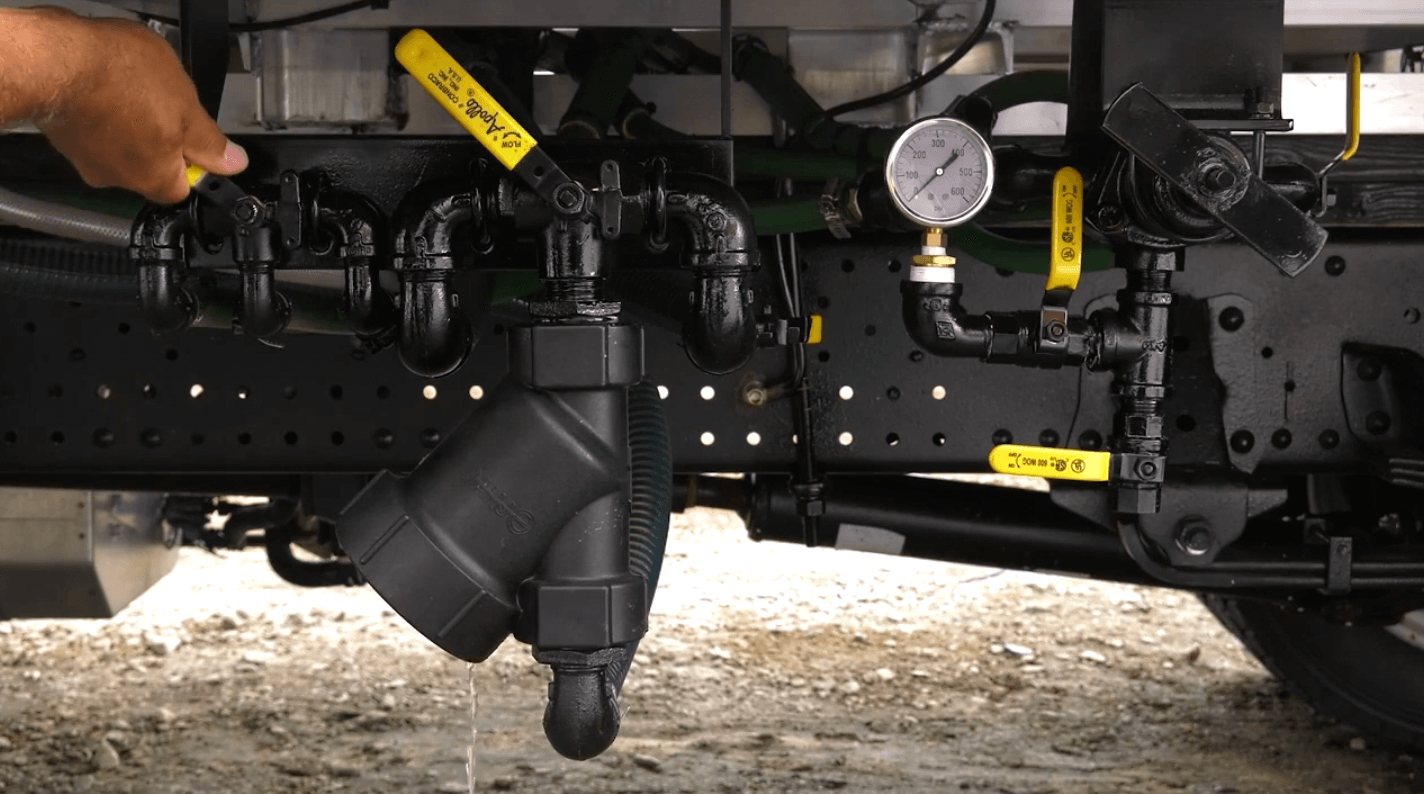

2. Drain All Fluids

Properly draining all fluids from your spray rig is crucial to prevent freezing and damage. Start by emptying the tank completely. Then run the pump and hoses until no liquid remains in them. Don’t forget to drain the plumbing and any pressure relief valves. Be sure to dispose of any leftover chemicals in accordance with local regulations.

3. Inspect and Replace Parts

Perform a thorough inspection of your spray equipment, checking for any signs of wear and tear. Replace any damaged or worn-out parts, including hoses, seals, gaskets, and nozzles. It’s better to replace these components now than to discover issues when you’re ready to use the rig again in the spring.

4. Lubricate Moving Parts

Lubrication is essential to prevent rust and keep moving parts in good condition. Apply a suitable lubricant to valves, hinges, and pump componentsto help protect against corrosion and increase the chances that everything will operate smoothly when you start using the rig again.

5. Store in a Dry, Protected Area

Where you store your spray rig during the winter months is critical. Choose a dry, protected area such as a garage, shed, or storage facility. Ensure that the area is well-ventilated to prevent condensation, which can lead to rust and corrosion. Cover your equipment with a tarp or specialized cover to keep dust and debris out.

6. Prevent Pest Infestations

Rodents and other pests may seek shelter in your equipment during the winter. To prevent this, seal any openings in your storage area that could serve as entry points. Consider placing pest repellents or traps in the vicinity to deter unwanted visitors.

7. Perform Regular Checkups

While your spray rig is in storage, don’t forget to periodically check on it. Inspect for any signs of damage, corrosion, or pest infestations. If you notice any issues, address them promptly to prevent further damage.

By following these steps for cold-weather equipment maintenance, you can ensure that your spray rigs remain in excellent condition throughout the winter months. This proactive approach will save you time and money when spring arrives, as you’ll be ready to hit the ground running with equipment that’s in top shape.

Remember that regular maintenance is key to prolonging the lifespan of your spray equipment and ensuring that it operates at peak performance when you need it most. Invest the time now to safeguard your equipment and enjoy a hassle-free lawn care season in the months ahead.

If you have any questions about equipment maintenance or need replacement parts, don’t hesitate to reach out to Graham’s team of experts. We’re here to support you in keeping your spray rigs in the best possible condition year-round.